Process performance vs process capability understanding the differences is crucial for optimizing any process. This exploration delves into the nuances of these two concepts, highlighting their distinct characteristics and interrelationships. We’ll examine metrics, influencing factors, data analysis techniques, and practical examples to gain a clear understanding of how to leverage both to drive process improvement.

Understanding the difference between process performance and process capability is essential for achieving efficiency and quality. Performance focuses on the current output of a process, while capability looks at the process’s inherent potential to produce within specified tolerances. This distinction is key to identifying areas for improvement, whether it’s increasing output, reducing variation, or a combination of both.

Defining Process Performance and Capability: Process Performance Vs Process Capability Understanding The Differences

Understanding the performance and capability of a process is crucial for any organization aiming for efficiency and quality. Effective processes lead to improved output, reduced costs, and enhanced customer satisfaction. This blog post delves into the nuances of process performance and capability, highlighting their differences and the metrics used to measure them.Process performance and capability are often used interchangeably, but they represent distinct aspects of a process.

Process performance focuses on the current state and how well the process is functioning, while process capability evaluates the process’s potential to consistently meet predetermined specifications.

Process Performance Definition

Process performance describes the current operational effectiveness of a process. It assesses how well the process is functioning under existing conditions. This includes factors like speed, efficiency, and adherence to established procedures.

Key Metrics for Process Performance

Several metrics are used to gauge process performance. These include:

- Throughput Rate: The rate at which the process produces output. For example, a manufacturing process producing 100 units per hour has a higher throughput rate than one producing 50 units per hour.

- Cycle Time: The time it takes for a process to complete from start to finish. Reducing cycle time is often a key objective to improve process performance.

- Defect Rate: The percentage of output that does not meet quality standards. A lower defect rate signifies better process performance.

- Utilization Rate: The proportion of available time that the process is actively used. High utilization rates indicate efficient use of resources.

- Lead Time: The time taken between the initiation of a process and the delivery of the output. A shorter lead time often indicates a more responsive and efficient process.

Process Capability Definition

Process capability assesses the process’s potential to consistently meet predetermined specifications. It focuses on the inherent variability of the process, rather than its current state. This involves understanding the process’s potential to produce conforming output.

Key Metrics for Process Capability

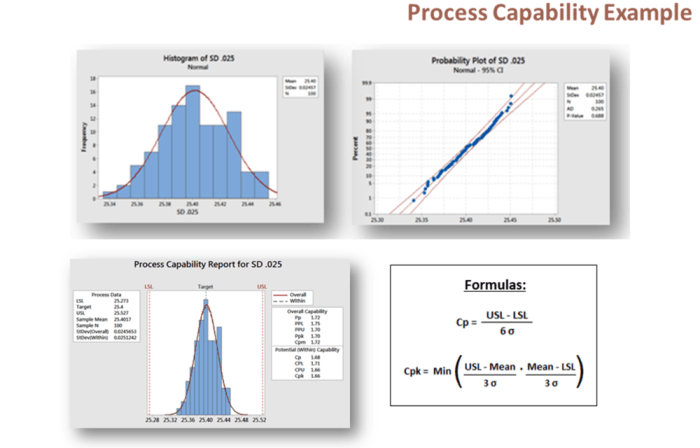

Process capability is evaluated using metrics that quantify the process’s ability to produce output within specified tolerances. These metrics are often derived from statistical process control (SPC) data. Common metrics include:

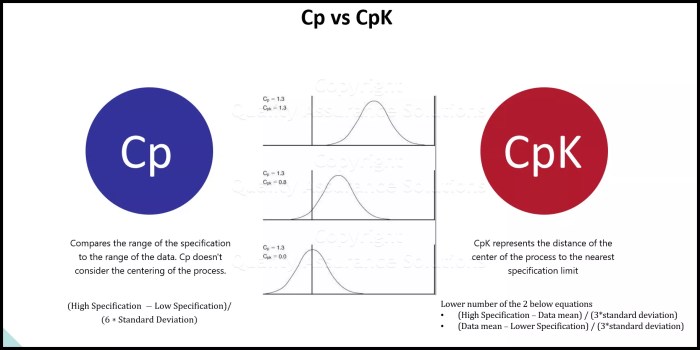

- Cp and Cpk: These indices measure the process’s capability relative to the specification limits. Cp focuses on the inherent potential of the process, while Cpk considers the process’s actual performance and the center of the process relative to the specification limits. A higher Cpk value suggests a greater ability to meet specifications.

- Process Sigma: A measure of process variability, often used in Six Sigma methodologies. A higher sigma level indicates a lower defect rate and greater capability.

- Pp and Ppk: These indices are similar to Cp and Cpk, but they are calculated using historical data and are useful when a process is unstable.

Comparing Process Performance and Capability

Process performance and capability, while related, differ significantly in their focus and application. Process performance assesses the current state of the process, while capability evaluates its potential. One can have a highly performing process that is not capable of meeting specifications, or a capable process that is not performing well due to external factors. A balance between both is necessary for achieving optimal process results.

| Metric | Process Performance | Process Capability |

|---|---|---|

| Focus | Current operational effectiveness | Inherent potential to meet specifications |

| Metrics | Throughput, cycle time, defect rate, utilization, lead time | Cp, Cpk, Process Sigma, Pp, Ppk |

| Purpose | Identify areas for improvement in current operation | Assess the process’s potential to meet quality standards |

Understanding the Relationship

Process performance and capability are intertwined concepts, both crucial for effective manufacturing and service delivery. Understanding their relationship is key to optimizing processes and achieving desired outcomes. This section delves into how these two concepts influence each other, creating a dynamic interplay that needs careful consideration.Process capability, essentially the inherent potential of a process, sets the upper and lower bounds for performance.

Performance, on the other hand, is the actual output of the process over a period of time. The relationship is not simply one of cause and effect; it’s a feedback loop where performance data informs adjustments to enhance capability, and improved capability in turn allows for higher performance.

Process Capability’s Influence on Performance

Process capability directly impacts the expected range of output. A highly capable process, meaning one that consistently produces outputs within tight specifications, will generally exhibit higher performance. This is because variations are minimized, leading to fewer defects and increased output within the desired parameters. Conversely, a process with low capability will produce outputs that are more likely to fall outside the acceptable range, thus impacting performance by increasing the rate of defects and inconsistencies.

For instance, a machine with a narrow tolerance range for producing bolts will consistently generate bolts within the required diameter. This capability directly translates into high performance.

Process Performance’s Influence on Capability

Process performance data provides valuable insights into the actual behavior of a process. Monitoring performance metrics like yield, cycle time, and defect rate allows for identification of areas where the process falls short of its capability. Data from performance analysis can be used to identify sources of variation and potential process improvements, thereby increasing capability. By tracking performance over time, trends can be observed and used to predict future performance.

For example, if a manufacturing process consistently produces more defects than anticipated, performance data reveals that the process is not fully capable. Analyzing this data may reveal root causes such as faulty machinery or inadequate training. Addressing these root causes will enhance the process’s capability.

Interplay Between Concepts

The interplay between process performance and capability is dynamic. A process with high capability does not automatically guarantee high performance. External factors, such as environmental conditions or human error, can significantly influence performance, even if the process itself is highly capable. Similarly, a process with low capability might still exhibit high performance if the process deviations happen to fall within the acceptable range.

Therefore, it’s critical to consider both capability and performance metrics simultaneously to gain a complete understanding of a process.

Illustrative Flowchart

Understanding the factors influencing process performance and capability is crucial for optimizing operations and achieving desired outcomes. Process performance reflects the current output of the process, while capability speaks to its inherent potential. By pinpointing the positive and negative influences on both, businesses can proactively adjust their strategies and resources to enhance overall effectiveness.Process performance and capability are interconnected.

A process with high capability but poor performance may indicate bottlenecks or inefficiencies in the execution phase. Conversely, a process with high performance but low capability might be producing acceptable results now, but will struggle to maintain quality or meet future demands. A thorough understanding of the driving factors behind both is essential for long-term success.

Positive Influences on Process Performance

Effective training and development programs for personnel significantly enhance process performance. Dedicated training improves employee skills, leading to higher quality output and reduced errors. Well-defined roles and responsibilities also contribute to better performance. Clear communication and collaboration among team members lead to a smoother workflow, minimizing delays and maximizing output. Motivated employees, with clear objectives and recognition for achievements, consistently deliver higher performance.

Negative Influences on Process Performance

Lack of adequate resources, including equipment, materials, and personnel, directly hinders process performance. Inefficient work processes, characterized by unnecessary steps or redundancies, lead to delays and lower output. Poor communication and collaboration among team members can disrupt workflows, causing bottlenecks and missed deadlines. A poorly managed or unclear quality control process results in defects, requiring rework and further impacting performance.

Positive Influences on Process Capability

Process capability is enhanced by the implementation of robust quality control systems. These systems proactively identify and correct deviations from standard operating procedures, ensuring consistency and quality. Investing in advanced technologies, like automated equipment or sophisticated software, allows for higher precision and accuracy in process execution. Well-maintained equipment and a planned preventative maintenance schedule minimize breakdowns and downtime, ensuring consistent high-quality performance.

Understanding the difference between process performance and process capability is crucial for any business, especially when it comes to technology services. High performance doesn’t automatically mean high capability. To attract more business buyers in today’s competitive market, you need to demonstrate not just that your technology services perform well, but also that they have the capability to consistently deliver high-quality results.

This means focusing on robust processes that are capable of handling fluctuations and maintaining quality, a critical factor that often gets overlooked. Learning how to clearly articulate this to potential clients is key to success, as explained in this insightful guide on how to get more business buyers of technology services in todays market. Ultimately, focusing on process capability over just performance ensures long-term client satisfaction and sustained business growth.

Negative Influences on Process Capability

Inadequate equipment maintenance and a lack of preventative measures lead to equipment malfunctions, resulting in variability and reduced capability. Unstable process inputs, including raw materials or environmental factors, contribute to variability and reduced capability. Inconsistent training or poor quality control procedures result in variability in the final product, reducing the process’s overall capability. A poorly designed process, lacking optimization for efficiency and quality, directly impacts the process’s capability.

Examples of Impacting Factors

A manufacturing company using outdated machinery for a critical step in their production process might face inconsistent product quality (low capability) despite having highly motivated workers (high performance). Conversely, a company with excellent equipment and a well-defined process but a lack of training for new employees may face high defect rates, impacting both performance and capability.

Table: Factors Affecting Process Performance and Capability

| Category | Positive Influences | Negative Influences |

|---|---|---|

| Performance | Employee training, clear roles/responsibilities, effective communication, motivation | Lack of resources, inefficient processes, poor communication, inadequate quality control |

| Capability | Robust quality control, advanced technologies, well-maintained equipment, optimized process design | Inadequate equipment maintenance, unstable process inputs, inconsistent training, poorly designed processes |

Analyzing Process Performance Data

Uncovering the hidden insights within process performance data is crucial for continuous improvement. Effective analysis helps identify bottlenecks, inefficiencies, and areas needing adjustments. This involves more than just looking at numbers; it’s about understanding the underlying patterns and trends to drive proactive change.Process performance data is rich with information, offering a window into the inner workings of a process.

By analyzing this data, we can identify opportunities to optimize the process, leading to higher quality outputs, reduced costs, and increased efficiency. This analysis enables a deeper understanding of the process, enabling better decision-making and resource allocation.

Examples of Process Performance Data

Process performance data encompasses various numerical metrics. Common examples include cycle times, defect rates, throughput, and capacity utilization. For instance, a manufacturing process might record the time it takes to complete each step in the production line, the percentage of defective products, the total output per hour, and the percentage of equipment running. Data points might include the number of units produced per shift, the number of customer complaints, and the average response time to customer inquiries.

These data points, when collected and analyzed, offer a comprehensive view of process performance.

Methods for Evaluating Process Performance

Several methods exist for evaluating process performance. These include statistical process control (SPC) charts, which track process data over time, helping to identify patterns and deviations from the norm. Other methods include calculating process metrics like mean, standard deviation, and capability indices (e.g., Cp, Cpk). These metrics provide insights into the consistency and stability of the process.

Understanding the difference between process performance and process capability is crucial, especially when optimizing customer loyalty programs. For example, a robust Salesforce loyalty management service, like the one offered by salesforce loyalty management service b2c b2b , can significantly impact performance metrics. However, it’s vital to remember that achieving optimal customer loyalty isn’t just about a fancy platform; a deep understanding of the underlying process capability is equally important to ensure lasting results.

Furthermore, analyzing historical data can reveal trends and seasonality that influence process performance.

Statistical Tools for Evaluating Process Performance

Statistical tools play a pivotal role in analyzing process performance data. These tools provide a framework for identifying patterns, trends, and outliers in the data. Common tools include histograms, control charts, Pareto charts, and scatter plots. Histograms visually represent the distribution of data, helping to identify the central tendency and variability. Control charts track process data over time, flagging potential issues and helping to maintain process stability.

Pareto charts identify the most significant contributors to a problem, while scatter plots illustrate the relationship between two variables. By utilizing these tools, we gain a deeper understanding of the data, allowing for informed decision-making.

Steps Involved in a Process Performance Analysis

A structured approach to process performance analysis is essential for effective results. This systematic approach ensures that no critical aspect is overlooked, leading to a more comprehensive and actionable understanding.

| Step | Description |

|---|---|

| 1. Define the Process | Clearly identify the process being analyzed. |

| 2. Collect Data | Gather relevant data points over a sufficient period. Ensure data accuracy and completeness. |

| 3. Organize Data | Organize and prepare the collected data for analysis, typically using spreadsheets or databases. |

| 4. Analyze Data | Employ statistical tools and methods to analyze the data, looking for trends, patterns, and outliers. |

| 5. Interpret Results | Draw conclusions from the analysis and identify areas for improvement. |

| 6. Implement Improvements | Develop and implement strategies to address identified issues and enhance process performance. |

Analyzing Process Capability Data

Unveiling the hidden potential of your processes requires a deep dive into process capability data. This involves more than just gathering numbers; it’s about understanding the inherent variability within your process and comparing it to the desired specifications. Effective analysis helps identify bottlenecks, pinpoint areas for improvement, and ultimately boost overall efficiency.

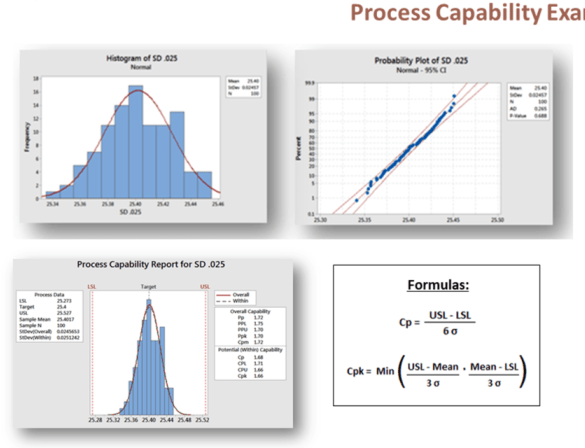

Examples of Process Capability Data (Numerical)

Process capability data is typically numerical. Consider a manufacturing process producing metal rods. Examples of data points might include:

- Diameter measurements (in millimeters) of 100 rods.

- Tensile strength (in megapascals) of 50 rods.

- Weight (in grams) of 25 rods.

These numerical values, collected over time, provide a picture of the process’s performance.

How to Analyze Process Capability Data (Numerical)

Analyzing numerical process capability data involves a systematic approach. First, collect a representative sample of data points. Then, calculate key statistical measures like the mean, standard deviation, and range. These metrics reveal the central tendency and dispersion of the process output. A key aspect of this analysis is understanding the relationship between the process output and the customer’s specifications.

Steps Involved in a Process Capability Analysis

A process capability analysis typically follows these steps:

- Data Collection: Gather a sufficient number of data points to represent the process’s performance. The sample size will depend on the process variability and desired level of confidence.

- Data Analysis: Calculate the mean and standard deviation of the data set. Determine the upper and lower specification limits (USL and LSL) defined by customer requirements or design specifications.

- Capability Indices Calculation: Calculate process capability indices (like Cp, Cpk, and Pp, Ppk) to evaluate the process’s ability to meet the specifications. These indices measure the process’s performance against the specification limits.

- Interpretation: Interpret the results of the capability indices. Higher values generally indicate better process capability. Compare the calculated capability indices to industry benchmarks or target values for the specific process.

- Process Improvement: Identify areas for process improvement based on the analysis. If the process is not capable, implement corrective actions to reduce variability and improve performance.

Statistical Methods for Evaluating Process Capability

Various statistical methods are employed to evaluate process capability. Common methods include:

- Normal Distribution Assumption: Many process capability analyses assume a normal distribution of the process output. This assumption allows for the use of standard statistical methods.

- Capability Indices (Cp, Cpk, Pp, Ppk): These indices quantify the process’s ability to meet the specification limits. They provide a numerical measure of the process’s capability.

- Control Charts: Control charts are used to monitor process performance over time. They help identify trends, patterns, and potential causes of variation.

Metrics for Evaluating Process Capability

Several metrics are used to evaluate process capability. Here are some key metrics:

- Cp: Process capability index. It measures the ratio of the specification width to the process spread, assuming the process is centered within the specification limits.

- Cpk: Process capability index. It measures the process capability, considering the process location (mean) relative to the specification limits.

- Pp: Process performance index. Similar to Cp, but it considers the actual process performance (mean and standard deviation) and not the ideal process performance (i.e., centered process).

- Ppk: Process performance index. Similar to Cpk, but it considers the actual process performance and not the ideal process performance.

Comparing Process Capability Analysis Methods

| Method | Description | Advantages | Disadvantages |

|---|---|---|---|

| Cp | Measures the process’s potential capability assuming it’s centered. | Easy to calculate and understand. | Doesn’t account for process centering. |

| Cpk | Considers process centering and measures the process’s capability to meet specifications. | More comprehensive than Cp. | Can be misleading if the process is significantly off-center. |

| Pp | Measures the process’s performance based on the actual process parameters. | Reflects the actual process performance. | Doesn’t consider the ideal process location. |

| Ppk | Measures the process’s performance based on the actual process parameters and considering the process location. | Most accurate measure of process performance. | Can be more complex to interpret. |

Interpreting Results and Improving Processes

Interpreting process performance and capability analysis results is crucial for identifying areas needing improvement and driving efficiency. Effective interpretation leads to targeted interventions, ultimately enhancing output quality and reducing waste. This section delves into the practical application of these analyses, showcasing how to translate data into actionable steps for process optimization.Process analysis isn’t just about gathering data; it’s about understanding the underlying reasons behind performance and capability gaps.

By identifying root causes and implementing corrective actions, organizations can significantly enhance their operational efficiency and product quality. A well-structured approach to interpreting results and implementing improvements is key to successful process optimization.

Interpreting Process Performance Analysis Results

Process performance analysis focuses on the average output of a process over a period. Understanding the average performance, along with the variation in that performance, is crucial for pinpointing areas requiring attention. Interpreting these results involves examining measures such as cycle time, throughput, defect rate, and other key performance indicators (KPIs). A high average but substantial variation suggests instability in the process, potentially indicating underlying issues.

Conversely, a low average performance may indicate a systematic problem requiring a broader review.

Understanding the difference between process performance and process capability is key for any business. Performance measures how well a process is currently operating, while capability focuses on the process’s potential. This is crucial for identifying bottlenecks and optimizing your workflows. Want to get your hands dirty with website creation? Trying out WordPress for free without a domain or hosting can be a great way to explore your options before diving in headfirst.

how to try WordPress for free without a domain or hosting This hands-on experience will give you a better sense of the technical aspects, which ultimately connects back to understanding process performance and capability.

Interpreting Process Capability Analysis Results

Process capability analysis assesses a process’s ability to consistently produce outputs within acceptable limits. This analysis uses statistical methods to determine whether the process is capable of meeting customer specifications. Interpretation involves understanding capability indices like Cp, Cpk, and Pp, which measure the process’s capability relative to the customer specifications. High values for these indices indicate a high likelihood of producing output within the desired range.

Conversely, low values highlight potential issues requiring adjustments.

Using Analysis Results to Improve Processes

Process analysis results should not be viewed in isolation. Instead, they should serve as a catalyst for process improvement initiatives. The interpretation of these results should lead to identifying the root cause of any issues. Once identified, corrective actions can be implemented to address the problem, leading to improved process performance and capability. This might include training staff, adjusting equipment, or modifying workflows.

Strategies for Enhancing Process Performance and Capability, Process performance vs process capability understanding the differences

Effective process improvement strategies involve a combination of proactive and reactive approaches.

- Implementing Lean Principles: Lean methodologies focus on eliminating waste and optimizing efficiency. This includes streamlining workflows, reducing inventory, and improving material flow. Examples include implementing 5S methodology for workplace organization or value stream mapping for workflow visualization.

- Statistical Process Control (SPC): SPC involves monitoring process parameters and detecting deviations from the target. Implementing SPC helps in preventing issues before they escalate and maintaining process consistency.

- Process Re-engineering: Re-engineering involves a fundamental review and redesign of the entire process to improve efficiency and effectiveness. This may involve redefining roles, changing procedures, or adopting new technologies.

- Training and Skill Development: Investing in training for employees is essential to enhance their skills and knowledge. Trained personnel can better identify and resolve process issues, leading to improved performance.

Practical Examples of Process Improvements Driven by Analysis Results

A manufacturing company noticed a high defect rate in their final assembly process. Process capability analysis revealed that the process was not capable of meeting the required tolerances. This led to the identification of a problem with the calibration of a key piece of equipment. Calibration adjustments and staff retraining resulted in a significant reduction in defects and improved process capability.

Another example is a customer service department experiencing high call resolution times. Performance analysis showed variations in agent handling times. Implementing training on call handling procedures and optimizing call routing systems led to a reduction in average call resolution time.

Improvement Strategies Table

| Improvement Strategy | Description | Potential Impact |

|---|---|---|

| Lean Principles | Eliminate waste, streamline workflows, improve material flow. | Increased efficiency, reduced costs, improved throughput. |

| Statistical Process Control (SPC) | Monitor process parameters, detect deviations from target. | Reduced defects, improved process stability, minimized variability. |

| Process Re-engineering | Fundamental review and redesign of the entire process. | Significant improvements in efficiency and effectiveness. |

| Training and Skill Development | Enhance employee skills and knowledge. | Improved process understanding, faster problem-solving, reduced errors. |

Illustrative Examples

Understanding process performance and capability is crucial for optimizing efficiency and quality. Real-world examples help solidify these concepts and demonstrate how improvements can be made. This section provides practical illustrations, from a struggling process to a high-performing one, highlighting the impact of process improvement initiatives.

A Process with Low Performance and Low Capability

A common example of a process with low performance and low capability is a poorly managed mailroom in a small business. Mail sorting and delivery are slow, with frequent errors in routing and missing or delayed items. The process is not standardized, with varying levels of skill among staff, and insufficient equipment. This leads to a high error rate and delays in receiving and delivering important documents, impacting customer satisfaction and business operations.

The low performance is evident in the long processing times and the high number of errors. The low capability is demonstrated by the inability to consistently meet the desired output quality and delivery times.

A Process with High Performance and High Capability

Consider a highly automated manufacturing line producing electronic components. The process is well-defined, with clear standards and procedures. Automated equipment ensures high speed and accuracy, with minimal human intervention. Robust quality control measures at each stage of production help maintain a high level of consistency in product quality. The high performance is evident in the rapid production rate and the low defect rate.

The high capability is shown by the ability to meet strict tolerances and consistently produce components meeting stringent quality standards.

A Process Improvement Project

A process improvement project focused on improving both performance and capability could involve a retail store’s order fulfillment process. Initially, orders were frequently late or incomplete, and customer satisfaction was low. The project implemented a new inventory management system, standardized order processing procedures, and trained staff on the new processes. The improved system tracked inventory in real-time, reducing stockouts and improving order accuracy.

Standardized procedures reduced order processing time. This improvement resulted in a significant reduction in order fulfillment time and a substantial increase in customer satisfaction. The project improved both the speed (performance) and the accuracy (capability) of the order fulfillment process.

Visual Representation of Process Performance and Capability

A common visual representation of process performance and capability is a control chart. A control chart plots data points over time, allowing for the identification of trends and patterns. For instance, a control chart tracking the number of defects per unit in a manufacturing process can reveal if the process is stable or if there are special causes affecting the quality.

Histograms can also visually represent the distribution of process output, showing the capability of the process to produce outputs within certain limits.

Case Study: Improving Customer Service Response Times

A telecommunications company experienced long wait times for customer service calls. This led to frustrated customers and negative reviews. The process involved routing calls to agents, and the wait times varied significantly. The company analyzed call handling times, agent availability, and call routing protocols. The analysis revealed bottlenecks in the call routing system and inconsistent agent response times.

The improvement project focused on implementing a new call routing system, providing agents with improved training, and creating a more efficient workflow. The result was a substantial reduction in average wait times and a marked increase in customer satisfaction. The new system improved the process performance and capability by optimizing the call routing and improving agent efficiency.

Summary Table of Case Studies

| Case Study | Process | Initial Performance | Initial Capability | Improvement |

|---|---|---|---|---|

| Mailroom Management | Mail sorting and delivery | Slow, frequent errors | Inconsistent, low quality | Implementation of standardized procedures, additional staff training, and improved equipment. |

| Manufacturing Line | Electronic component production | High speed, low defect rate | Consistent quality, meets tolerances | Maintaining automation and robust quality control measures. |

| Order Fulfillment | Retail order processing | Late deliveries, incomplete orders | Low accuracy | New inventory management system, standardized procedures, staff training. |

| Customer Service | Call handling | Long wait times, inconsistent responses | Inefficient routing, inconsistent agent performance | New call routing system, agent training, improved workflow. |

Final Thoughts

In summary, process performance and capability are interconnected yet distinct concepts. Understanding their individual metrics and interdependencies allows for a holistic approach to process optimization. By analyzing data, identifying influencing factors, and implementing improvement strategies, businesses can enhance both process performance and capability, leading to significant gains in efficiency and quality. The journey toward optimizing a process often involves a blend of data-driven analysis and practical problem-solving.