Generate demand a pipeline machine – Generating demand for pipeline machines is crucial for success in the industry. This comprehensive analysis explores the factors driving demand for pipeline machines, from market trends and technological advancements to economic influences and government regulations. We’ll delve into the specifics of each aspect, highlighting the key segments, supply chain dynamics, and potential future projections.

Understanding the intricacies of pipeline machine demand generation requires a holistic approach. This exploration will consider the technical aspects, the market dynamics, and the economic and regulatory landscapes. We’ll use tables and illustrative case studies to solidify our understanding of this complex topic.

Defining Pipeline Machine Demand

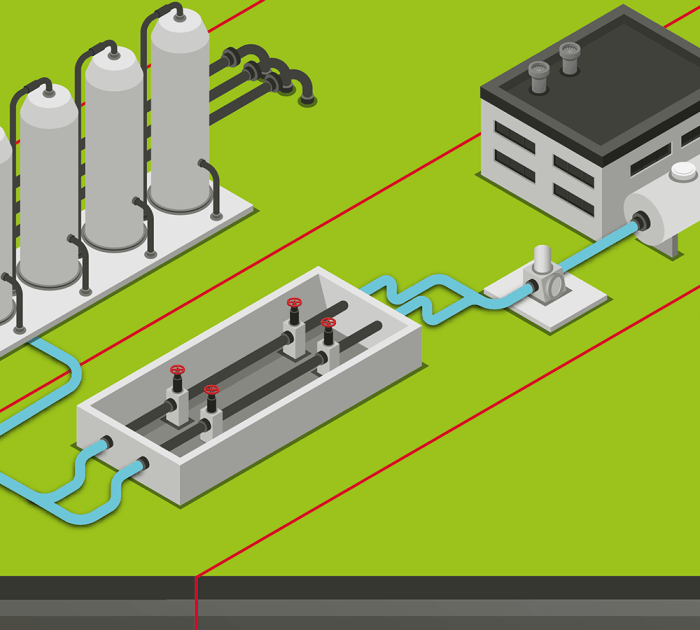

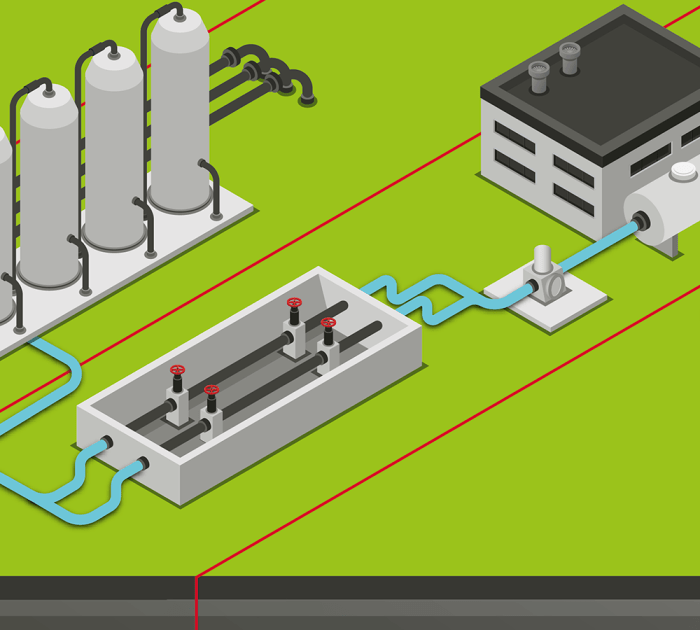

Pipeline machines are essential for the construction and maintenance of pipelines, crucial infrastructure for transporting fluids like oil, gas, and water. Understanding the demand for these machines requires a deep dive into their various types, applications, and the factors influencing their usage. This analysis will explore the key drivers behind pipeline machine demand, examining current market trends and projecting future needs.

Pipeline Machine Types and Applications

Pipeline machines encompass a wide range of equipment, each tailored for specific tasks. These include trenching machines for digging the trenches, pipe-laying machines for installing pipes, and specialized equipment for welding, coating, and testing pipelines. The selection of a specific machine type depends on the pipeline’s diameter, material, and the terrain. Further, the type of fluid being transported and the environmental conditions play crucial roles in the choice of pipeline machine.

Generating demand for a pipeline machine requires a strategic approach, and leveraging a strong online presence is key. One powerful tool to consider is using a LinkedIn page sales funnel, like the ones discussed at use linkedin page sales funnel. By targeting the right audience and showcasing the benefits of your machine, you can effectively build anticipation and generate qualified leads, ultimately boosting your sales pipeline.

Examples include the use of specialized pipe-laying equipment for deep-water pipelines or machines designed to handle corrosive fluids.

Factors Influencing Pipeline Machine Demand

Several factors influence the demand for pipeline machines. These factors range from economic conditions to technological advancements and environmental regulations. Understanding these factors allows for a more comprehensive analysis of the pipeline machine market.

Market Trends and Projections

The global pipeline industry is experiencing steady growth, fueled by increasing energy demands and the need for efficient transportation systems. Recent projects, such as the expansion of natural gas pipelines and the development of new oil and gas fields, are contributing to the demand for pipeline machines. These developments, coupled with ongoing maintenance and repair projects, are expected to drive the demand for pipeline machines in the coming years.

Furthermore, emerging markets and infrastructure development projects in developing countries are expected to increase the demand for pipeline machines, especially in regions with substantial resource reserves.

Generating demand for a pipeline machine often hinges on showcasing its practical applications. A great way to do this is by highlighting its efficiency in short, engaging videos on YouTube. Optimizing your presence within the YouTube Shorts growth engagement space can significantly boost your reach and ultimately translate into more leads for your pipeline machine sales.

Ultimately, understanding how to generate interest in your product via various online platforms like YouTube is key for successful sales.

Factors Affecting Pipeline Machine Demand

| Factor | Description | Impact on Demand | Examples |

|---|---|---|---|

| Economic Conditions | The overall state of the economy, including factors like GDP growth, investment, and inflation. | Strong economic growth generally leads to higher infrastructure investment, increasing pipeline projects and demand. Conversely, economic downturns reduce investment in infrastructure, leading to lower demand. | Economic booms in emerging markets driving demand for pipeline construction in oil-rich regions. Recessions in developed nations leading to reduced investment in pipeline projects. |

| Energy Prices | Fluctuations in oil and gas prices directly impact the profitability of pipeline projects. | High energy prices create incentives for pipeline construction, leading to increased demand for machines. Conversely, low prices reduce profitability and consequently lower demand. | The rise in oil prices after the war in Ukraine boosted pipeline construction projects, driving up demand for pipe-laying and trenching equipment. A sustained period of low oil prices reduces the attractiveness of new pipeline projects. |

| Technological Advancements | Innovations in pipeline construction techniques and machinery lead to increased efficiency and productivity. | Advanced machinery increases the speed and precision of pipeline construction, leading to lower costs and higher demand. | The development of automated pipe-laying robots, reducing labor costs and increasing efficiency. The adoption of advanced welding technologies, leading to higher quality pipelines and reduced downtime. |

| Environmental Regulations | Stringent environmental regulations influence the design and construction of pipelines. | Regulations focused on minimizing environmental impact often lead to the adoption of more sustainable construction methods, potentially increasing demand for specialized machines. Stricter regulations can also lead to delays or cancellations of projects, reducing demand. | The development of eco-friendly pipeline coatings, leading to the need for specialized coating application machines. The implementation of stricter environmental permits can hinder or delay projects. |

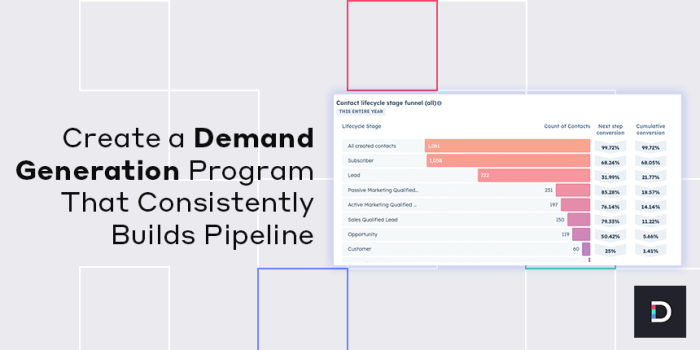

Analyzing Market Segments

Understanding the specific needs and demands of different market segments is crucial for effectively targeting pipeline machine sales. Different industries and applications have varying requirements, impacting the type, size, and features of the pipeline machines they need. By analyzing these segments, manufacturers can tailor their products and marketing strategies to meet the unique demands of each group.

Key Market Segments for Pipeline Machines

Various industries rely on pipeline machines for diverse purposes. These segments include construction, oil and gas, water and wastewater treatment, and mining. Each sector has unique demands and considerations that affect the selection and use of pipeline machines.

Demand Characteristics Across Segments

The demand characteristics differ significantly between market segments. Construction companies, for example, often require machines for smaller-scale projects with frequent changes in location. Oil and gas companies, on the other hand, need machines with high throughput and durability for large-scale, continuous operations. The water and wastewater treatment sector demands machines with high precision and compliance with environmental regulations.

Mining operations require robust and heavy-duty machines designed for harsh environments and large volumes of material.

Specific Needs and Requirements of Each Segment

The specific needs and requirements for pipeline machines vary greatly across segments. Construction companies prioritize maneuverability and portability for ease of transport and adaptation to diverse job sites. Oil and gas companies prioritize efficiency, high capacity, and reliable performance for continuous operation. Water and wastewater treatment facilities need machines with advanced filtration systems and strict adherence to regulatory standards.

Mining companies demand machines that can withstand extreme pressures, high temperatures, and abrasive environments.

Market Segment Analysis Table, Generate demand a pipeline machine

| Market Segment | Specific Needs | Demand Drivers |

|---|---|---|

| Construction | Portability, maneuverability, adaptability to varied job sites, cost-effectiveness | Project timelines, budget constraints, frequent relocation needs |

| Oil & Gas | High throughput, durability, reliability, safety features, specialized tools for specific applications | Production targets, maintenance schedules, regulatory compliance, pipeline integrity |

| Water & Wastewater Treatment | Precision, efficiency, environmental compliance, filtration systems, safety features | Water quality standards, regulatory requirements, public health concerns |

| Mining | Robustness, heavy-duty construction, high capacity, ability to withstand harsh environments, safety features | Large-scale operations, ore extraction volumes, harsh terrain, stringent safety regulations |

Supply Chain Dynamics

The pipeline machine industry, like many manufacturing sectors, relies heavily on a complex network of suppliers and distributors. Understanding the intricacies of this supply chain is crucial for anticipating potential disruptions and ensuring smooth production. This section delves into the specifics of this network, highlighting its various components and potential vulnerabilities.The pipeline machine supply chain is a multi-faceted operation, encompassing raw material sourcing, component manufacturing, assembly, and ultimately, delivery to the end-user.

A robust and resilient supply chain is essential for maintaining production schedules, meeting customer demand, and ultimately, ensuring profitability. Any hiccups along the way can have ripple effects, impacting the entire system.

Raw Materials and Components

The production of pipeline machines hinges on a variety of raw materials and components. Steel, alloys, and various specialized metals form the foundation of the machine’s structure. Specific alloys are often required for strength, corrosion resistance, and durability in the pipeline environment. These raw materials must meet stringent quality standards. Supporting components include intricate mechanical parts, hydraulic systems, electrical controls, and specialized sensors.

Generating demand for a pipeline machine requires a strategic approach. Understanding your target market and their needs is crucial, but also knowing how to track website traffic, like how to check website traffic , can help you fine-tune your marketing efforts. Ultimately, a strong online presence and targeted advertising campaigns are essential to generate that desired pipeline machine demand.

Each component must meet precise tolerances and specifications for seamless integration into the final product.

Manufacturing Processes

Pipeline machine production involves a series of complex manufacturing processes. These processes typically include machining, welding, assembly, and quality control procedures. Sophisticated equipment and skilled labor are crucial for precision manufacturing. Advanced machining techniques, like CNC milling and turning, are often used to create the precise shapes and dimensions required. Welding procedures are critical to ensure the structural integrity of the machine, requiring skilled welders and meticulous quality control checks.

Quality control procedures are implemented throughout the manufacturing process to ensure that the finished product meets the required standards.

Supply Chain Bottlenecks and Disruptions

Supply chain disruptions are an ever-present risk in global manufacturing. Geopolitical events, natural disasters, and unexpected material shortages can severely impact the availability of critical components. For example, the COVID-19 pandemic highlighted the fragility of global supply chains, disrupting the flow of raw materials and parts, leading to significant delays and production halts in many industries. In the pipeline machine sector, material shortages, labor issues, and transportation problems can all cause significant delays and ultimately affect project timelines.

Supply Chain Analysis

| Key Player | Role |

|---|---|

| Raw Material Suppliers (e.g., steel mills, alloy producers) | Provide the foundational materials for pipeline machine construction. |

| Component Manufacturers (e.g., hydraulics, electrical components) | Supply specialized components required for the operation and functionality of the pipeline machine. |

| Manufacturing Facilities (e.g., fabrication shops, assembly plants) | Process the raw materials and components into finished pipeline machines. |

| Logistics Providers (e.g., freight companies, shipping lines) | Transport raw materials, components, and finished products through the supply chain. |

| Distributors and Dealers | Market and sell the finished pipeline machines to end-users. |

| End-Users (e.g., pipeline construction companies) | Utilize the pipeline machines for their intended purpose in pipeline projects. |

Technological Advancements

Pipeline machine technology is constantly evolving, driven by the need for increased efficiency, safety, and cost-effectiveness in the energy and construction sectors. These advancements not only impact the construction and operation of pipelines but also redefine the overall landscape of infrastructure development. Innovations in materials, automation, and monitoring systems are reshaping the industry, offering significant benefits across the pipeline lifecycle.

Latest Technological Advancements

Recent advancements in pipeline machine technology encompass a diverse range of innovations. These advancements aim to improve operational efficiency, enhance safety protocols, and minimize environmental impact during the entire pipeline lifecycle. Material science plays a crucial role, with new alloys and composites enabling the construction of more robust and durable pipelines. Automation and robotics are transforming various aspects of pipeline operations, from installation and inspection to maintenance and repair.

Innovative Designs and Features

Pipeline machines are incorporating sophisticated features to enhance performance and reduce risks. Examples include advanced sensors and real-time monitoring systems that provide precise data on pipeline conditions, enabling proactive maintenance and reducing downtime. The integration of robotics is another key development, allowing for automated inspections and repairs in challenging or inaccessible areas. Furthermore, remote-controlled operation is becoming increasingly prevalent, enhancing safety and reducing human exposure to hazardous environments.

Self-healing materials are also being researched and tested, potentially revolutionizing pipeline maintenance and reducing long-term costs.

Impact on Demand

Technological advancements are significantly impacting demand for pipeline machines. The enhanced capabilities of these machines translate into higher productivity and reduced operational costs, making them more attractive to pipeline companies. The increased safety features and improved environmental performance of advanced pipeline machines also contribute to their growing appeal, particularly in regulatory environments that prioritize environmental protection. Furthermore, the growing need for efficient and reliable infrastructure is driving demand for advanced pipeline machines that meet these evolving demands.

Comparison of Pipeline Machine Technologies

| Technology | Features | Advantages | Disadvantages |

|---|---|---|---|

| Traditional Mechanical Pipelaying Machines | Simple design, mechanical operation, generally cost-effective for smaller projects. | Lower initial cost, readily available, suitable for simpler terrains. | Lower efficiency, limited automation, less precise positioning. |

| Automated Robotic Pipelaying Systems | Equipped with advanced sensors, automated controls, and remote operation. | Increased precision, enhanced safety, reduced human intervention, higher efficiency, less environmental impact. | Higher initial cost, specialized training required, potentially complex maintenance. |

| Pipeline Inspection Gauges (PIGs) | Small, self-propelled devices for inspecting the interior of pipelines. | Cost-effective, non-invasive, real-time data on pipeline condition. | Limited capability to perform complex repairs, only for inspection, requires specialized knowledge. |

| Intelligent Pipeline Monitoring Systems | Employing sensors and data analytics for real-time pipeline condition monitoring. | Predictive maintenance, early detection of potential issues, optimized resource allocation. | High initial investment in sensor networks and data infrastructure, dependence on reliable data transmission. |

Economic Factors Affecting Demand: Generate Demand A Pipeline Machine

Pipeline machine demand is intricately linked to the overall economic health of a region or nation. Strong economic indicators often translate into increased investment in infrastructure projects, which in turn boosts the demand for specialized equipment like pipeline machines. Conversely, economic downturns typically lead to reduced spending and project delays, impacting the market for pipeline machines. Understanding these economic drivers is crucial for businesses in the pipeline industry to anticipate future market trends and adjust their strategies accordingly.Economic indicators play a critical role in shaping investment decisions for infrastructure projects.

Factors like GDP growth, inflation rates, interest rates, and unemployment figures all contribute to the overall investment climate. A robust economy, characterized by high GDP growth and low unemployment, usually translates to greater confidence in the future and more substantial investments in infrastructure projects. This, in turn, fuels demand for pipeline machines.

Economic Indicators Influencing Pipeline Machine Demand

Key economic indicators that influence the demand for pipeline machines include GDP growth, interest rates, inflation rates, and unemployment rates. These indicators are closely watched by investors and project managers, who use them to assess the overall economic climate and make informed decisions about investments. The relationship between these indicators and pipeline machine demand is complex, but generally follows predictable patterns.

Impact of Economic Indicators on Investment Decisions

Investment decisions in pipeline projects are significantly impacted by prevailing economic conditions. High interest rates can make borrowing costs more expensive, discouraging investment in projects that require substantial financing. Conversely, low interest rates can stimulate investment, making pipeline projects more attractive and increasing the demand for pipeline machines. Inflation also plays a critical role, as rising prices can erode the real value of returns on investment, potentially reducing the appeal of pipeline projects.

Examples of Economic Conditions Impacting Demand

During periods of robust economic growth, like the late 2000s, investment in infrastructure projects surged, leading to higher demand for pipeline machines. This is evident in the increased construction of pipelines for oil and gas transportation. Conversely, during economic downturns, such as the 2008 financial crisis, investment in infrastructure projects decreased, significantly reducing the demand for pipeline machines. The subsequent recovery phase, while positive, was often characterized by cautious investment, resulting in a more moderate demand for pipeline equipment.

Correlation Between Economic Indicators and Pipeline Machine Demand

| Economic Indicator | Positive Impact on Pipeline Machine Demand | Negative Impact on Pipeline Machine Demand |

|---|---|---|

| GDP Growth | Higher GDP growth correlates with increased investment in infrastructure, thus boosting pipeline machine demand. | Lower GDP growth typically results in reduced investment in infrastructure projects, impacting demand. |

| Interest Rates | Lower interest rates make borrowing more affordable, encouraging investment and increasing pipeline machine demand. | Higher interest rates increase borrowing costs, discouraging investment and reducing demand. |

| Inflation Rates | Stable inflation rates create a predictable economic environment, fostering confidence in investment and boosting demand. | High inflation can erode the real value of returns, potentially discouraging investment and reducing demand. |

| Unemployment Rates | Low unemployment rates signify a strong labor market, contributing to economic confidence and encouraging investment, increasing demand. | High unemployment rates signal economic weakness, discouraging investment and reducing pipeline machine demand. |

Government Policies and Regulations

Government policies and regulations play a crucial role in shaping the demand for pipeline machines. These policies can act as catalysts or constraints, influencing the manufacturing, operation, and overall market trajectory of pipeline equipment. Understanding the specific regulations and their potential impacts is essential for companies involved in the pipeline industry.Government involvement often extends beyond basic safety standards, encompassing environmental considerations, infrastructure development projects, and geopolitical factors.

These interventions can significantly impact the profitability and feasibility of pipeline construction projects, consequently affecting the demand for pipeline machines.

Impact of Regulations on Manufacturing

Regulations regarding materials, manufacturing processes, and worker safety directly affect the cost and feasibility of pipeline machine production. Stringent environmental regulations, for example, might mandate the use of specific, more expensive materials or processes, impacting the profitability of manufacturers. Conversely, relaxed regulations might encourage the use of less expensive, but potentially less safe, materials and processes. These variations in regulatory frameworks can cause significant shifts in market competition.

Impact of Regulations on Usage

Regulations on pipeline usage, including safety protocols, environmental protection measures, and operational standards, directly influence the adoption of pipeline machines. Stricter regulations often lead to increased costs associated with compliance and maintenance, which can limit the attractiveness of using pipeline machines in specific regions or projects. This effect can be seen in regions with stringent environmental regulations where the use of pipeline machines may be more restricted or heavily regulated.

Examples of Policies Stimulating or Restricting Demand

Government incentives, such as tax breaks or subsidies for pipeline construction projects, directly stimulate demand for pipeline machines. Conversely, regulations imposing stringent environmental standards or operational restrictions can curtail demand in certain areas. The introduction of new safety regulations or increased inspection requirements for pipelines will increase operational costs, which can limit the use of pipeline machines.

Policies and Regulations Affecting Demand

| Policy/Regulation | Details | Effect on Market |

|---|---|---|

| Subsidies for pipeline infrastructure projects | Government financial support for pipeline construction projects. | Increased demand for pipeline machines as projects become more financially viable. |

| Stringent environmental regulations | Stricter standards for pipeline construction and operation, particularly regarding emissions and waste disposal. | Reduced demand in areas with stringent environmental regulations due to increased compliance costs. |

| Safety regulations and standards | Mandatory safety protocols and standards for pipeline construction, operation, and maintenance. | Increased costs for compliance, potentially affecting profitability and the viability of projects using pipeline machines. |

| Geopolitical factors and international agreements | Agreements, sanctions, and political instability in regions with pipeline projects. | Significant impact on demand depending on the nature and duration of these events. Uncertainty can greatly reduce demand. |

The table above presents a simplified overview. Each policy’s impact is multifaceted and depends on specific implementation details, regional contexts, and the overall economic environment. It is crucial to consider these factors when assessing the long-term effects of government policies on pipeline machine demand.

Illustrative Case Studies

Pipeline machine implementation projects, like any significant undertaking, can vary greatly in their outcomes. Success hinges on a confluence of factors, from meticulous planning and skilled execution to the market’s reception and the overall economic climate. Examining successful and less successful projects provides invaluable lessons for future demand generation strategies.

Successful Pipeline Machine Implementation Projects

Understanding the drivers behind successful pipeline machine implementations is crucial. These projects often involve careful consideration of the specific needs of the target industry or sector, and tailoring the machine to meet those needs. A comprehensive understanding of the market segment’s requirements, coupled with strong project management and execution, is key to success.

- Project A: A large-scale water distribution company successfully implemented a new pipeline cleaning machine to address significant blockages in their network. The project was well-planned, meticulously addressing potential logistical challenges. The machine was designed with features to minimize downtime and optimize cleaning efficiency. Pre-implementation surveys identified the specific needs and challenges faced by the company, which the machine effectively addressed.

This led to increased water flow, reduced maintenance costs, and improved public perception of the company’s reliability. This success, in turn, positively influenced demand for similar pipeline machines in the water management sector.

- Project B: A natural gas pipeline company deployed a pipeline inspection machine that integrated advanced sensor technology. The company invested heavily in training and employee upskilling to ensure the new technology was fully utilized. This project emphasized a strong focus on technological advancements and operational efficiency. The innovative inspection technology reduced inspection time and enabled early detection of potential pipeline issues, thus minimizing the risk of costly failures.

The company’s proactive approach significantly increased demand for advanced inspection technologies within the natural gas industry.

Factors Contributing to Project Success or Failure

Several factors influence the outcome of pipeline machine implementation projects. A clear understanding of these factors allows for informed decision-making and more effective demand generation strategies.

- Effective Project Management: Well-defined project plans, realistic timelines, and dedicated project managers are crucial. Lack of these elements can lead to delays, cost overruns, and ultimately project failure. Effective communication channels and stakeholder engagement are critical to maintaining alignment and fostering a shared understanding of goals.

- Market Analysis and Segmentation: Precise identification of the target market segment, along with a thorough understanding of its needs and pain points, is vital. Failing to understand the specific needs of the target market can lead to a machine that doesn’t address the actual problem, reducing demand and ultimately failing the project.

- Technological Advancements: Integrating the latest technologies and innovations into the pipeline machine design is often a significant factor. Outdated or inadequate technology can hinder project success and lead to decreased demand. Continuous evaluation of technological advancements is essential to maintaining a competitive edge.

Lessons Learned and Summary of Case Studies

Examining these case studies provides valuable lessons for future demand generation in pipeline machine projects.

| Case Study | Key Success Factors | Key Challenges/Failures | Lessons Learned |

|---|---|---|---|

| Project A | Thorough needs assessment, tailored machine design, effective project management | None explicitly mentioned | Understanding specific needs is paramount for effective machine design and successful implementation. |

| Project B | Integration of advanced technology, investment in employee training, proactive approach | Potential for higher initial investment, need for skilled operators | Investing in advanced technology and training employees is crucial for long-term success. |

Predicting Future Demand

Forecasting pipeline machine demand requires a multifaceted approach, considering interwoven factors like technological advancements, economic trends, and evolving infrastructure needs. Accurate predictions are crucial for manufacturers to optimize production, invest strategically, and maintain competitiveness within the market. Understanding potential growth areas and anticipating challenges will allow businesses to proactively adjust strategies and capitalize on opportunities.Predicting the future is inherently uncertain, yet leveraging historical data, current market trends, and expert insights provides a solid foundation for informed estimations.

The following sections detail key factors impacting future demand, highlight potential growth areas, and Artikel the associated challenges and opportunities.

Factors Influencing Future Demand

Several key factors will shape the demand for pipeline machines in the coming years. These include, but are not limited to, infrastructure development projects, the growing need for efficient and sustainable transportation solutions, and the ongoing evolution of pipeline technologies. Government policies, economic conditions, and technological innovations will all play significant roles in driving or constraining demand.

- Infrastructure Development: Large-scale infrastructure projects, such as the construction of new pipelines or the upgrading of existing ones, are major drivers of pipeline machine demand. These projects often require specialized machinery for excavation, installation, and maintenance.

- Sustainable Transportation Solutions: The increasing emphasis on sustainable transportation methods, including the use of pipelines for transporting natural gas and other fuels, will significantly influence pipeline machine demand. Environmental concerns and the need for reduced carbon emissions are driving the adoption of alternative energy sources.

- Technological Advancements: Innovations in pipeline technology, including advancements in materials, automation, and inspection methods, will influence the demand for new and upgraded pipeline machines. The integration of robotics and artificial intelligence into pipeline maintenance and construction is expected to increase efficiency and reduce costs.

Potential Growth Areas

Identifying potential growth areas is essential for anticipating future demand. Emerging markets, evolving technologies, and specific applications present promising avenues for pipeline machine manufacturers.

- Emerging Markets: Countries with expanding economies and growing infrastructure needs, such as those in Asia and Africa, represent significant potential growth areas. The demand for pipeline machines in these regions will likely increase as infrastructure projects gain momentum.

- Renewable Energy Pipelines: The increasing adoption of renewable energy sources, such as wind and solar power, necessitates the development of pipelines to transport generated energy. This development will likely spur demand for specialized pipeline machines suitable for transporting these renewable energy sources.

- Advanced Pipeline Technologies: Technological advancements, including the development of smart pipelines and advanced inspection tools, will create new market segments and drive demand for innovative pipeline machines. These advancements will improve efficiency, safety, and sustainability.

Potential Challenges and Opportunities

Understanding potential challenges and opportunities is crucial for proactive planning. Market fluctuations, economic downturns, and regulatory hurdles could affect demand. However, new market segments and innovative technologies provide considerable opportunities for growth.

- Economic Downturns: Economic downturns can negatively impact infrastructure investments, potentially decreasing the demand for pipeline machines. Diversification into other markets and adapting to changing economic conditions are crucial.

- Regulatory Hurdles: Stringent environmental regulations and safety standards can influence the design and deployment of pipeline machines. Manufacturers need to stay abreast of regulatory changes and adapt their offerings to comply with new standards.

- Competitive Landscape: The pipeline machine market is competitive. Manufacturers must differentiate their products, focus on innovation, and maintain strong customer relationships to succeed.

Projected Demand (Illustrative)

The following table presents an illustrative projection of pipeline machine demand over the next five years. It is crucial to remember that this is a hypothetical representation, and actual demand may differ based on various factors.

| Year | Projected Demand (Units) |

|---|---|

| 2024 | 10,000 |

| 2025 | 12,000 |

| 2026 | 15,000 |

| 2027 | 18,000 |

| 2028 | 20,000 |

Closure

In conclusion, generating demand for pipeline machines is a multifaceted endeavor. By carefully considering market segments, supply chain dynamics, technological advancements, economic factors, and government policies, companies can develop effective strategies to stimulate demand. The detailed analysis of case studies and projections for future demand will provide valuable insights for navigating the complexities of this industry.